Collection: Products

Check out our top-tier carbon fiber parts designed to enhance the style and performance of your G80 M3 and G82/G83 M4. From sleek front lips to aggressive rear diffusers, our carbon fiber parts are crafted to fit seamlessly and elevate your ride.

Shop now and redefine your driving experience with the finest BMW parts and accessories! All of our G8X carbon fiber products are crafted from premium-grade dry/pre-preg carbon fiber, ensuring top-tier quality and precise fitment for your BMW.

-

BMW F30/F80/F82 Aggressive High Kick Style Dry Carbon Fiber Trunk Spoiler

Regular price $249.00 USDRegular priceUnit price / per -

BMW F30/F80/F82 CS Style Dry Carbon Fiber Trunk Spoiler

Regular price $225.00 USDRegular priceUnit price / per -

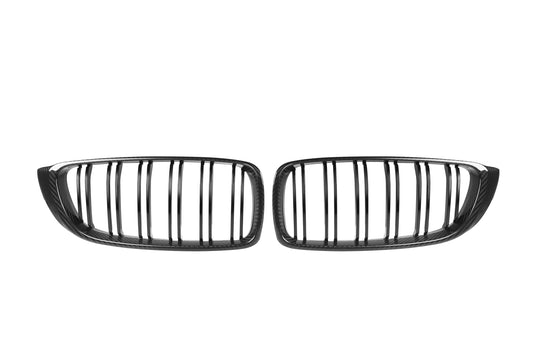

BMW F80/F82 Double Slat Dry Carbon Fiber Front Kidney Grille Replacement

Regular price $299.00 USDRegular priceUnit price / per -

BMW F80/F82 M3/M4 Performance Inspired Dry Carbon Fiber Front Lip Splitter

Regular price From $599.00 USDRegular priceUnit price / per -

BMW F80/F82/F83 Dry Carbon Fiber 3-Piece V-Style Rear Diffuser Set

Regular price $700.00 USDRegular priceUnit price / per -

BMW F80/F82/F83 OEM Style Dry Carbon Fiber Mirror Cap

Regular price $269.00 USDRegular priceUnit price / per -

BMW F80/F82/F83 Performance Inspired Dry Carbon Fiber Rear Diffuser

Regular price $499.00 USDRegular priceUnit price / per -

BMW F80/F82/F83 Performance Inspired Dry Carbon Fiber Side Skirts

Regular price $599.00 USDRegular priceUnit price / per -

BMW F80/F82/F83 Performance Style Dry Carbon Fiber Seat Backrest Covers 4 PCS

Regular price $479.00 USDRegular priceUnit price / per -

BMW G20 3-Series 330i/M340i LCI, M-Performance Style Dry Carbon Fiber Diffuser

Regular price $699.00 USDRegular priceUnit price / per -

BMW G20 330i/M340i LCI M-Performance Style Dry Carbon Fiber Front Lip

Regular price $519.00 USDRegular priceUnit price / per -

BMW G20 330i/M340i M-Performance Style Dry Carbon Fiber Side Skirt

Regular price $549.00 USDRegular priceUnit price / per -

BMW G20 330i/M340i Pre-LCI M Performance Style Dry Carbon Fiber Front Lip

Regular price $649.00 USDRegular priceUnit price / per -

BMW G20 330i/M340i Pre-LCI M-Performance Style Dry Carbon Fiber Diffuser

Regular price $659.00 USDRegular priceUnit price / per -

BMW G80 M3 CS Style Dry Carbon Fiber Rear Trunk Spoiler

Regular price $209.00 USDRegular priceUnit price / per$215.00 USDSale price $209.00 USDSale -

BMW G80/G82 M3/M4, PSM Style Aggressive High Kick Dry Carbon Fiber Rear Trunk Spoiler

Regular price $219.00 USDRegular priceUnit price / per$239.00 USDSale price $219.00 USDSale

Everything You Need to Know About Carbon Fiber: Production, Molds, Materials, Finishing, And More

Everything You Need to Know About Carbon Fiber: Production, Molds, Materials, Finishing, And More

Molds in Carbon Fiber Production: Most G8X carbon fiber products we sell are made out of metal mold! Either aluminum or steel, to ensure precision fitment.

Molds play a crucial role in shaping carbon fiber products and determining their precision, durability, and cost. The three main types of molds used are resin, fiberglass, and metal.

Resin Molds

- Applications: Suitable only for wet carbon fiber production.

- Advantages: Low cost and easy to produce.

- Disadvantages: Resin molds have a short lifespan (10–50 uses), are prone to deformation, and lack precision. Products made with resin molds often suffer from poor fitment and texture inconsistencies due to low-temperature curing (30–40°C).

Fiberglass Molds

- Applications: Used for wet carbon fiber and lower-grade dry carbon.

- Advantages: More durable than resin molds, with a moderate production lifespan (20–50 uses). They can handle curing temperatures of 120–140°C, producing products with smoother textures and better fitment.

- Disadvantages: Fiberglass molds degrade over time and lack the precision of metal molds.

Metal Molds (what most of our products are made from)

- Applications: Essential for high-quality dry carbon fiber production.

- Advantages: Metal molds (usually aluminum or steel) are extremely durable (500–5,000 uses), do not degrade over time, and offer unparalleled precision. They can withstand the high temperatures and pressures required for autoclave curing, ensuring fitment and consistent textures.

- Disadvantages: Metal molds are expensive to produce, requiring precision CNC machining and significant upfront investment.

The high cost of metal molds makes them ideal for high-end, mass-production applications where quality and consistency are paramount.

Materials: The Core of Carbon Fiber Products

Carbon fiber products are defined by the type of carbon fiber cloth used. There are two main categories: dry cloth and pre-impregnated cloth.

Pre-Impregnated Carbon Fiber Cloth (Prepreg)

- Characteristics: The fabric is pre-soaked with resin at around 150°C, ensuring a consistent weave, higher strength, and excellent heat resistance.

- Applications: High-performance products like automotive body panels, aerospace components, and luxury goods.

Common Carbon Fiber Cloth Used in Automotive:

- 200g 3K Carbon Fiber Cloth: Lightweight and commonly used for automotive exterior non-weight bearing parts.

- 240g 3K Carbon Fiber Cloth: Slightly denser for added strength.

- 6K and 12K Carbon Fiber Cloth: Heavier, more robust options for structural applications.

The weight (e.g., 240g) represents the weight per square meter, and the "3K" indicates 3,000 fibers per bundle.

Painting and Finishing: Adding the Final Touch

Painting and finishing are critical to enhancing both the durability and aesthetics of carbon fiber products. Commonly used paints and coatings include:

- Acrylic Paint: Low cost, but with poor adhesion, limited durability, and low-temperature resistance. Often used for outdoor furniture but unsuitable for high-performance applications.

- UV-Cured Paint: A premium option that uses epoxy resin for a glossy "piano finish." It’s resistant to high temperatures and delamination, with strong adhesion and quick curing cycles.

- Polyurethane (PU): High-cost epoxy-based paint known for its flexibility, durability, and resistance to aging and weathering. It provides excellent repairability and surface hardness.

Painting Techniques:

- Four Primer Coats, One Top Coat: Poor adhesion and prone to delamination.

- Three Primer Coats, One Top Coat: Better adhesion and durability.

- Two Primer Coats, One Top Coat: Exceptional clarity, showcasing the fiber texture for a premium look.

Proper finishing not only protects the carbon fiber from UV damage and aging but also highlights its iconic woven texture.